The Ultimate Guide on Sourcing From China

Hey everyone, Greg here.

If you’ve been following us for the last few months, you’ve noticed we’ve been getting A LOT of ecommerce businesses lately on our marketplace. We’ve been growing this audience for some time, but a lot of you out there who are wanting to get into the ecommerce space are still missing some crucial bits of knowledge.

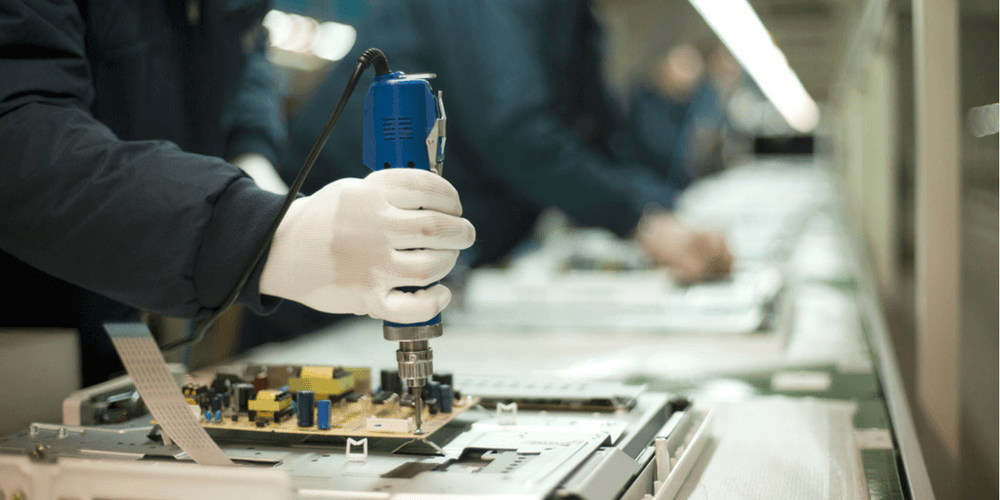

One of the most crucial pieces of running a successful ecommerce business is how you go about actually sourcing your product. That is why today I want to introduce David Wood with IMEX Sourcing. He is a professional that has been living and breathing sourcing for IMEX’s clients. They help people successfully find the right manufacturer, broker the right kind of contracts, and help their clients avoid the common pitfalls ecommerce entrepreneurs can sometimes find themselves falling into.

Whether you’re just getting started in ecommerce or wanting to level up your sourcing knowledge, this monster post is for you.

All right, all that being said, I’ll let David take it away from here!

You might be looking into buying a Fulfillment by Amazon (FBA) business from the Empire Flippers marketplace. You know the business works by sourcing goods directly from China into Amazon FBA warehouses, and you know the profit and loss statements show promise.

But buying a business that imports from China without doing your due diligence would be a huge mistake. Sourcing is a dense subject and will require serious study to master, even in cases of purchasing a stable business.

Sourcing from China has a long learning curve, especially for those who are new to the business and are just interested in stocking their FBA stores for the first time. What can an average importer expect in their process of sourcing and shipping from China?

We at IMEX Sourcing Services have been sourcing from China for nearly seven years and have learned a lot in the process, particularly by helping clients with little knowledge of China make a significant return on investment (ROI) in their ecommerce businesses.

We’ll take you through the whole sequence of sourcing by breaking down all the major questions that can arise once you’ve purchased an ecommerce website and want to start sourcing the goods from China. After reading this article, you’ll know the lay of the land in sourcing and be fully prepared to embark on your own sourcing journey.

An Introductory Briefing

Abbreviations and Terms Used in the International Trade World

The very first step any importer takes into this world is learning the acronyms. The world of international trade is full of acronyms, and these have a significant effect on your pricing and contract terms. You’ll experience plenty of headaches later on if you’re not clear on these terms from the start. We will refer to them throughout the rest of this article, so if you see an unfamiliar acronym, return to this section for an explanation.

AQL: Acceptable Quality Limit. This refers to the percentage of defects that are permissible for different tiers of defect severity.

CBM: Cubic Meter. The international standard unit of measurement for freight cargo.

FBA: Fulfillment by Amazon. Amazon’s program allowing third-party sellers to sell on Amazon, where Amazon manages the storage and fulfillment of goods, and handles the customer service for sellers.

FCL: Full Container Load. Refers to cargo freight requiring a whole shipping container. The goods might not actually occupy the whole container, but some importers may find it’s more cost-effective to use FCL shipping anyway as there are additional costs and inefficiencies in using less than full container loads.

Incoterms: There are many different incoterms, which refer to different pricing agreements between the supplier and the importer. Here are some of the most common terms:

- EXW, meaning “Ex Works,” is where the supplier has no responsibility for the goods after they have been packaged, meaning the importer must pay to have the goods transported from the supplier.

- FOB, meaning “Free On Board,” is where the supplier assumes responsibility up to the point the goods are loaded for shipment. The supplier is not responsible for the goods during or after the shipment.

- CIF, meaning “Cost, Insurance, and Freight,” is where a supplier takes all legal responsibility for the goods until they are delivered to the destination port.

LCL: Less Than Full Container Load. As you might guess, this means cargo freight not occupying a full container. Generally, these shipments are consolidated with other LCL shipments to fill a container.

MOQ: Minimum Order Quantity. This is the smallest order a supplier will accept. For suppliers, larger orders are always better, as the overhead is too expensive for smaller orders. Even if there is no issue with overhead, suppliers have their own MOQs from their sub-suppliers; hence, they are often not able to take smaller orders as they won’t be able to procure raw materials/components from their suppliers.

QC: Quality Control. Various processes involved in controlling the quality of a product, including drafting contracts and QC checklists, along with carrying out the inspections to verify the quality of the goods.

RFQ: Request for Quote. This refers to when importers ask suppliers to give them a quote on the production cost for any product.

The vocabulary in this industry is quite extensive, but becoming familiar with the above list of acronyms should be enough to understand this article and start diving deeper. But before going deep into industry nuances, let’s start with some tips that may help first-time importers.

What Are Some Tips for First-Time Importers?

Have Realistic Expectations.

We often receive emails asking for a new product on impossibly short timelines, as well as for rock-bottom pricing with high QC standards. Fast, cheap, and quality tend to exclude one another. If you manage to get this kind of too-good-to-be-true deal with a Chinese supplier, it’s almost guaranteed that either they are attempting to entice you with a disingenuous quote or finding ways to cut corners in the production process. (Neverminding, for now, the possibility of outright fraud.)

The First Order Always Takes a Lot Longer Than People Expect.

For the first order, multiply your quoted production time by three to get a true expectation of the production duration. The first order always takes two to three times longer because you have to set up the process — you have to settle product and package designs, get a sample of the product, and approve the final version before production begins.

People Tend to Forget Common Costs.

Don’t forget costs like buying and shipping samples, fees from Amazon or other platforms, customs inspection at both ends of the line, and returns. If you forget these costs, you may be surprised to find you don’t make margins at the end of the day.

In China, Order Size and Repeat Potential Is King.

If you want top quality with low production costs, you’re going to have to order big and order often. Chinese suppliers operate on razor-thin margins, and they don’t want to waste time finding new prospects or adapting their production lines. If you’re a solid buyer, they’ll be more willing to negotiate with you on virtually every aspect of your business with them.

What Are the Difficulties of Importing?

Some importers find that their sourcing journey starts off with everything going well: an eager-to-please supplier, passed inspections, and few delays. They consider themselves as having mastered the importing game after a successful order, are pleased that they’re making great ROI, and are proud of having done it all themselves.

The truth is, eventually every importer runs into issues whether they’re brand new or seasoned professionals.

Problems can vary in severity:

- Delays in shipments (so common as to be expected)

- Communication difficulties resulting in defective products

- Suppliers raising prices at the last minute

- Intellectual property infringements

- Quality fade (the quality of the production fading over time as a result of the factory cutting corners to expand margins)

If you have one container load that can’t be sold in the Western market, the loss could be enough to wipe out several months of previous profits. A shipment of $50,000 USD worth of goods that fails some compliance law and fails to get past customs will put you $50,000 in the hole — and that’s before having to pay to ship and destroy the goods.

It is important to know what you’re doing and create contingencies for the eventual problems. The process is becoming easier with advances in globalization and technology, though it’s still simplest —and in most cases, cheapest — to hire a sourcing and QC company to manage everything for you while you focus on product research, marketing, and scaling your company.

The Sourcing Stage

What Are the Different Types of Suppliers?

You will find that there are three major types of suppliers: factories, traders, and sourcing companies.

Factories

China’s manufacturing factories range in size, quality, production capacity, and product ranges, and because the industry is changing, they are breaking stereotypes all the time. They have improved significantly over the last couple of decades in terms of offering better labor practices to their workers, and many are actively implementing the country’s new regulations on pollution.

Factories may lack effective English communicators as they specialize in production rather than marketing/advertising/outreach. When communicating with them on Alibaba, you may suspect they are using translation software for communication.

Despite the translation issue, factories are the experts in production. If they have experience in manufacturing your product, they will be able to understand your technical requirements. However, they are not marketers and may not understand the needs of the Western market, so you’ll have to be clear with your factories on your expectations of your product.

They are best to work with if you have these three things going for you:

- You understand the product and its manufacturing process really well

- You need almost no customization for the product

- Service quality is not hugely important for you

However, be aware that many suppliers advertising themselves at trade shows or on Alibaba as factories may not actually produce any goods at all but are instead trading companies that sell on behalf of the factory without the extensive experience in producing the products they advertise.

Trading Companies

Trading companies are middlemen who source products from multiple factories and mark-up the products and resell them; often, they specialize in certain industries or product categories. Trading companies dominate as the connection between factories and the Western world, often serving as the sales and marketing arm for factories, but that is changing as more factories invest in direct sales. Unfortunately, in China, trading companies often claim to be factories, which is why due diligence during the initial stages is so important.

You may find it easier to work with a trading company; they often offer better communication, a bigger product range, and sometimes smaller MOQs. Since trading companies may represent dozens of factories, they will have fairly large catalogs of products, potentially spanning many industries, meaning you could likely centralize a lot of your product ordering from them. And because of their affiliate relationship with factories, they may be able to get deals importers can’t ordinarily get, such as small MOQs.

However, working with a trading company means you may have to deal with inflated prices, have difficulty in customizing a product, or have a harder time controlling quality due to lack of direct communication with the factories. Additionally, trading companies don’t maintain stock for their products, so requesting a sample will require them to source the product, resulting in longer order periods. Finally, as they sell on behalf of factories, their loyalties are split between their clients and those manufacturers, which may make them ineffective for resolving disputes with suppliers.

These disadvantages should be considered against their advantages. In most cases, importers prefer to work directly with the manufacturer, but there are good trading companies out there that do high-quality work with strong customer service, so long as you’re aware of their disadvantages.

Trading companies should not be confused with sourcing companies, which are entirely different operations.

Sourcing Companies

Sourcing companies fully manage importing and QC operations for their clients, essentially becoming their client’s office in China by managing their sourcing, developing product samples, negotiating and managing contracts, ensuring QC, and frequently handling logistics. They differ from trading companies by maintaining independence and not earning commissions from sales on behalf of factories. Consequently, they have no vested interest in protecting manufacturers and instead represent their client importer’s interests in China to retain their business.

Sourcing companies can vary significantly in terms of their size, scope, and sophistication. There are freelancer sourcing agents, small- to medium-sized sourcing companies with three to 15 employees, and very large sourcing companies that work primarily for the retail giants.

Different sourcing companies fit with different kinds of buyers. Some are great for buyers just starting out and others for buyers who have larger orders and different priorities. For example, at IMEX Sourcing Services, we tend to work with medium-sized and large buyers who have been selling for at least one year. Our focus is more on quality issues, problem solving, and helping our clients scale and launch new products with “speed.”

The advantage of working with a sourcing company is that they can leverage preexisting supplier networks for better per-unit costs and conflict resolution, such as disagreements that could arise over delivery schedules, quality of the goods, variance in price, intellectual property infringements, or other issues. A good sourcing company will also work to understand specific consumer needs and try to fix problems with a product by understanding them, rather than offer an under-researched quick fix that simply gets to the next order.

Sourcing companies also tend to better understand compliance, certification, and international trade procedures, which helps ensure that the product being imported meets the compliance standards and regulations of the importing market. It is important to note, though, that sourcing companies aren’t experts at setting compliance standards, only enforcing them on the ground.

However, sourcing companies may be fairly expensive to work with, particularly for small orders, because sourcing companies require a significant amount of manpower-intensive work. Investing in and maintaining a network of suppliers with strong relationships, finding the right company for the client, negotiating quotes, and then engaging in back and forth communication on samples is risky for a sourcing company if the client declines to pursue a project. For that reason, sourcing companies tend to charge more for their services.

When using sourcing companies, it is important that you know exactly what you want to source, because unlike trading companies, sourcing companies don’t promote or recommend any products and most aren’t product specialists.

How Do I Find Suppliers?

There are different avenues for finding suppliers, and it is not difficult to do so in today’s age.

Online Channels

Just about everyone knows about Alibaba these days, and for good reason — it’s huge and simple to use, and most large suppliers in China maintain a presence here. This is a great place for any would-be importer to start doing their research.

It should be noted that finding suppliers on Alibaba is the quantity-over-quality approach — there are tons of suppliers online catering to foreign markets, resulting in:

- Plenty of “suppliers” who are either not legitimate or haven’t been around long enough to be considered a safe investment

- A ton of trading companies posing as factories (upwards of 70 percent of the total business-to-business portal suppliers)

- Higher prices, at least without serious negotiations

That being said, Alibaba is a great place to start your sourcing journey, particularly if you are interested in doing smaller orders, i.e., below $10,000. There are also plenty of gems on it, and many serious importers are able to make significant margins using this marketplace if they do their due diligence in vetting their suppliers.

There are other platforms as well, all with different value propositions. Global Sources, Made in China, and HKTDC are three good alternatives, which attempt to solve the quality issues mentioned above to varying degrees by pre-vetting the suppliers using their platform.

Trade Shows

The next step up from doing online research would be the classic method of finding a supplier: going to China for a trade fair. Canton Fair is the mother of all trade shows. An importer who goes to the Canton Fair with a specific product in mind, hunts down the right area for it in the fair, and finds several suppliers with samples on hand can start the negotiation right there. With Canton Fair being one of the biggest trade fairs in the world, you won’t be lacking opportunities.

However, just like Alibaba, the Canton Fair suffers from a quantity versus quality problem, and a huge fraction of all suppliers there are actually trading companies. Thus, it may be in the importer’s best interest to attend a more specialized event that pre-vets all factory attendees to ensure they all own the factories they claim to own. One such fair would be the Global Sources Trade Show in Hong Kong, which runs in the same time window as the bi-annual Canton Fairs, allowing importers to attend both events.

Trade fairs are a great way to get connected with suppliers, face to face, and quickly launch your sourcing game. They are also great if you are just looking to see what’s going on in the marketplace at large or to simply see what China has to offer in terms of products to import, as a lot of suppliers would use trade shows to launch their new products.

Sourcing Companies

You can also outsource this process to a sourcing company which will typically save you significant time in finding them yourself. This effectively makes the sourcing company your supplier.

A good sourcing company would have systems and processes in place to differentiate the traders from factories as well as processes for vetting the factories based on criteria provided by you. They should also be able to run background checks on the suppliers using government databases.

Wholesale Markets

There are many wholesale markets that can be found all around China featuring sellers looking for bulk buyers. They’ll have goods on display, and you can choose an item and make an order then for however many units you prefer.

You can place a smaller order with wholesale markets, since your orders won’t be required to satisfy large MOQs. If you are looking to buy ready stock (stock that doesn’t require customization and is ready to be sold) in small quantities or if you want to mix and match products, then wholesale markets are your best bet. It does mean, however, that customization or private labeling is normally not possible in such cases.

How Do I Differentiate Trading Companies From Factories?

Identifying manufacturers, or factories, in a field of trading companies is difficult, but there are strategies to separate them out. The first thing you can do to figure out if the organization you’re talking with is actually a manufacturer or a trading company is to ask them questions:

- “Are you a trading company?” There are plenty of ethical and honest trading companies in China that will simply tell you that they are a trading company.

- “Can we visit your factory?” A trading company may offer a vague answer, while a factory will encourage you to visit in order to increase the chance that you will place an order with them.

- “Are you open to a factory audit by a third-party inspection company?” Trading companies may not be comfortable with an audit since they will have to expose their source.

- “Can you tell me about [a technical process or material]?” Factories should be able to answer technical questions more specifically since they are actually manufacturing the product.

There are a few other strategies as well:

- Look at the Address. Factories’ addresses are likely to be in areas outside of a town or city. You can look for keywords like “Industrial Park/Zone.” Trading companies are more likely to be located in office buildings in a major city.

- Look at Their Product Range. Most factories in China are highly specialized and focus on making a very limited range of products. Therefore, if you see a booth carrying a fairly wide range of products, even within a specific industry, that could be indicative of a trading company.

These strategies typically distinguish trading companies from factories. That being said, a factory may be manufacturing one product but trading in other products, and thus may be playing trading company to your needs. These companies can be difficult to spot, as they may pass cursory background checks. The only sure-fire way to confirm whether they are the manufacturer of a specific product is to check out the production line for that product.

How Do I Do Due Diligence on Factories?

Due diligence is extremely important. While many factories are honest companies in China, there are also plenty of horror stories of suppliers taking the full payment for goods and disappearing into the sunset, being unable to effectively and reliably produce your product, shutting down in the event of troubled financial times, or being unable to provide paperwork to comply with trade regulations.

There are a few tactics you can use to perform due diligence on a potential supplier:

- Company Verification Reports: A verification report is done to ensure the factory is who they say they are and is something you can do fairly cheaply. This is the most basic form of due diligence — checking government records and databases to see if the company is legitimate and has been around for awhile with a registered address. However, this is not a foolproof method, because company credentials can be bought and sold fairly easily in China, meaning that a seven year old supplier’s credentials may have changed hands recently, effectively becoming a separate company and making their time in business not a reliable indicator of their legitimacy.

- Factory Audits: Factory audits are a more advanced form of due diligence where you have a third party essentially audit the factory on a battery of issues to assess their overall health, compliance, and capabilities. It involves looking into the company records and doing an on-site inspection to get a sense of the company’s compliance with local or international standards, documentation, and their processes for QC, among other features.

- Factory Visits: A classic due diligence check is simply going to China to see the factory for yourself; you can even see your goods in production this way. We recommend you do an in-person visit or have a trusted agent do it for you. As an added benefit, you may be able to hash out issues directly with the supplier, rather than doing a back and forth negotiation on samples.

Online platforms like Alibaba may provide some degree of due diligence on their suppliers using the above methods. However, as mentioned above, verification reports don’t necessarily show the complete picture, while “factory visits” by companies like Alibaba may mean nothing more than someone driving by the address and recording that it exists. Audits done by these platforms may be useful, but only if they are up-to-date with lots of information.

Oh, and you can forget about the “Gold Star Supplier” and other such titles on portals like Alibaba. This indicates nothing except the supplier purchased the title from the website.

Getting your supplier figured out is a huge task but it’s only the beginning of your sourcing operation.

What Is the Procedure for Sourcing From a Supplier?

Once you’ve found a supplier with the product you want to source, you can reach out to them with an RFQ.

They’ll send you some informal quotations, and if you’re happy with the prices, you can request product samples to get a feel for the actual product. Samples are extremely important in this business; you want to make sure you get the product you want instead of the product the factory wants to make, as well as getting a quality product instead of an inferior one.

The process normally takes a lot longer than most new importers anticipate. Most factories don’t have ready samples on hand (unless it’s a standardized commodity), and it generally takes 10 to 12 days to produce a sample. So you should plan for at least six to eight weeks from the time you brainstorm a product to having “approved samples” in hand. Then there is back and forth communication and often multiple rounds to get the samples perfected to the standard of the importer, sorting out specifications/components, packaging, etc.

How Do I Negotiate With Suppliers?

You’ll have two chances to really negotiate with suppliers — first, during the initial quotation phase, and second, after you’ve received the samples.

In doing these negotiations, the most fundamental aspect is specificity with your requirements for the product and for the order itself. Beyond that, it helps if you are able to communicate the value of your business to the supplier and stand out as a “hot prospect,” or someone who is ready to buy (not placing an idle RFQ) with solid capital to invest and great repeat potential. Showing these qualities will ensure the supplier takes an interest in getting back to you as soon as possible with the strongest and most accurate quote for your request.

Of course, if you’re just starting out, it’s paradoxical to demonstrate repeat orders if you haven’t placed your first order. But there are some ways to signal repeat potential to the supplier:

- Showing you have high product and market knowledge

- Approaching as a business as opposed to an individual

- Having a professional company website

- Providing a company introduction: A couple of lines about your business and your previous China imports make a big difference

Or, in other words, do your best to not appear to be a new importer. Do all these things to give greater gravity to your RFQs.

QC

How Can an Importer Control the Quality of Their Goods?

Chinese products have a bad reputation of being cheaply and poorly made. However, this is not always the case, and there are all kinds of factories in China, with many of them making world-class products.

The quality issues are often due to manufacturers either not understanding the requirements correctly or cutting corners during the production process. These issues can be avoided by having a strong QC checklist (a checklist of criteria that the goods must meet). You should have this and do inspections on the goods to verify that they are produced according to that checklist.

Getting that strong QC checklist is a whole other process that will obviously depend on the product, so it’s important for importers to understand their products, how they’re produced, and potential defects they can encounter.

Then it’s important to have a third party conduct the inspection, preferably by having a QC company go to the factory and inspect the goods prior to shipment. Or you can hire a company like IMEX Sourcing Services to manage the whole process, where we would have a detailed clause in the contract with the factory covering the inspection and what happens if something is wrong.

Sometimes, factories don’t want to allow third parties in to perform inspections, particularly if your order size is small. Nonetheless, that’s a pretty big red flag and call to change your supplier.

Lastly, make sure you have a contract, and it’s best if it’s bilingual. Obviously, that’s not possible for those without the resources to read and negotiate in Chinese. But at least an English contract will provide some basic protection in terms of being able to negotiate when things go wrong. More on this later.

How Much QC Should Be Done, and When?

If you don’t sign contracts, do due diligence, or do anything else, the very least QC you can do is have one pre-shipment inspection carried out on your goods by a third-party inspection company, and do it before you pay the balance on the goods.

The best time to do an inspection is before you pay the balance (with a 30 percent deposit, this would be 70 percent) to the factory because this is the time at which you have leverage with them. If you find issues, you can negotiate with them to try and fix those problems, but bear in mind fixing QC issues will eat into a manufacturer’s margins so they won’t be very flexible about this. Once the factory has 100 percent of the payment, you’re at their mercy.

Once the goods are at the destination port, it’s usually not feasible to send them back to China for fixes, as factories are generally not willing to pay the logistic costs for shipping.

What Should a Purchase Contract Between an Importer and a Supplier Specify?

A good contract needs to be as detailed as possible in the following areas:

- Product Specifications

- As many details regarding the product as possible.

- Payment Procedures

- How much, and when do payments happen?

- Typically, you should pay a 30 percent deposit to get production started, and then the remaining 70 percent only after the goods have passed the pre-shipment inspection and a Bill of Lading has been sent to you.

- Getting payment details correct is incredibly important, as a scamming supplier may ask for 100 percent of the payment before sending the Bill of Lading. Complying with this can result in the supplier disappearing and leaving the importer with no choice but to eat the cost of the whole shipment.

- Inspection Conditions and Environment

- It’s important to specify under what standards the goods will be inspected, who will do the inspections, and what will constitute a defect.

- Dispute Settlement Mechanisms

- In the event of a dispute, how is it resolved? Where is it resolved? What protections and guarantees are available to both parties?

- Compensation Clauses and Penalties

- What happens in the event of a delay or an inspection failure?

Of course, different products will require different contracts to suit their needs, for example, whether the products need to match a certain industry standard or certification. The contract is where you include such details.

Additionally, a contract should be bilingual or at least should be in Chinese for it to have legal validity. English-only contracts have almost no legal validity in China and enforcement will be impossible, but they will provide some basic level of protection.

Speaking of enforcement: We find that when your order value is below $50,000, the cost of actually enforcing a contract in Chinese courts normally outweighs the potential recovery. However, it is a very powerful negotiation tool, as whenever things go wrong, suppliers would normally blame it on a “communication gap.” When your agreement details are shown in black and white (and Chinese), most suppliers are willing to work with you and fix issues or even rework goods.

What Rate of Failure Is Considered Acceptable for an Inspection to Pass?

In an inspection, you should expect to see some defects but they should not be endemic. A lot of new importers get surprised and angry when they see any defects at all in their shipment. In reality, zero percent defects are not only very difficult to achieve for most consumer products, but can also be very expensive. (Not to mention, virtually no manufacturer would be willing to agree to these terms.)

All importers should expect to have some major and minor defects in their product and be ready to process returns to handle these, as processing returns is more cost-effective than ensuring your goods are 100 percent inspected with zero percent defects.

The acceptable rate of failure can vary depending on the product, but in general, inspection results are assessed by the AQL standards. If the goods have more defects than the specified threshold, the inspection is considered failed and the importer can either accept the result as it is or ask the supplier to rework the goods and then conduct new inspections on those. Of course, any goods that are found to be defective in passed inspections can be replaced or reworked by the supplier.

The AQL standards specify the following thresholds:

- Zero Percent Critical Defects

- Critical defects are defects that could cause harm in some way and result in the importer being liable for damages or responsible for a product recall.

- An example of a product that clearly had critical defects would be the Samsung Galaxy Note 7, well known for its propensity to literally explode.

- Up to 2.5 Percent Major Defects

- These are defects that would generally be considered unacceptable to a user — some part of the product might break or not function properly.

- Up to 4 Percent Minor Defects

- These defects might be something a user, in theory, might not mind, such as cosmetic damage like a scratch on the product. These should not significantly impact user experience.

What is considered a critical, major, or minor defect will clearly vary from product to product. Care must be taken to ensure the supplier understands how to avoid these defects, and also to ensure that your inspection company looks for these defects during inspections. The defects should also be defined early in the process in the contract.

What Are Lesser Known Issues in QC?

QC is a huge subject with endless niches, but there are a few common issues that are general enough to address in this guide.

QC Issues From Scaling

If an importer orders 5,000 units one month, finds success, and then orders 20,000 units the next, QC inconsistency can become a major issue — especially with smaller factories employing less than 50 workers.

What happens is, if they cannot meet the demand or they don’t have the production capacity, they will outsource production to another factory.

These outsourced products are produced under different conditions and by different people, which can lead to inconsistencies in the product. This process is not something that can be controlled by your contracts because there is no way to actually ensure companies aren’t engaging in this practice, though you can attempt to preempt it by ordering a mid-production inspection. In general though, it’s best to anticipate the problem and work with your supplier to ensure quality control being continuously assured, which may mean producing the goods in several batches.

Quality Fade

This is a common issue that arises only after your first few orders, and generally, once you start to feel comfortable in sourcing. Suppliers at this time may begin feeling that they have a solid grasp of the product manufacturing process of your product and feeling comfortable with their relationship with the client. Expecting the client to be complacent, they may begin finding ways of cutting costs in the manufacturing process and improving their own margins.

Sometimes, these corner-cutting measures are harmless, with the importer never noticing — it might be a change in the thickness of the material in cases where the thickness is not important. In other cases, it may be severe.

An amusing story comes from Poorly Made in China in which a shampoo’s chemical formulation was changed. The shampoo had no obvious changes except for that when in relatively cold weather, the shampoo became a blocky, jelly-like substance. The factory refused to release the formulations on the new product or confirm any changes had been made, claiming proprietary ownership over their new formulations (modified from the client’s original formulations). As the client was invested enough in the supplier with proprietary designs and formulations, they felt chained to the supplier and believed they had no choice but to simply complain to the factory and agree to price increases to resolve the issue. The supplier degraded the quality of the bottles and reduced the size of the labels, too.

A strong QC process is important here. But so is not giving in to complacency and always working to improve your products over time.

Assuming you’ve got your quality controlled, it’s time to consider how you’re getting the goods to your target marketplace.

Shipping Your Products

What Shipping Options Are Available?

There are three main ways to ship your freight: by sea, air, and courier. Each option has unique advantages and disadvantages.

Sea Freight

Sea Freight is the standard ocean shipping that everyone is familiar with. You have your goods loaded into containers seen everywhere at shipping yards, and then they get sent, slowly, across the ocean.

If your volume is large enough, you would ship using an FCL, with either a 20-foot, 40-foot standard, or 40-foot “high cube” container. If your goods are only a few CBMs, you would ship using an LCL shipment.

LCL shipments tend to be more expensive on a per CBM basis and often take 10 to 14 days longer than FCL shipments, since you are sharing a container with others, and the goods need to be consolidated at the original port and de-consolidated at the destination port — a process carried out by a separate third party called a groupage company.

Your forwarder/sourcing company will normally manage most of the paperwork required for clearing your goods through customs and paying haulage fees to get the items to your door or warehouse.

For most importers, sending by sea is the best way to get strong ROI as it’s the least expensive method. But it does take time. Depending on the origin and destination ports, you might be looking at months in between departure and arrival.

Air Courier

The Air Courier shipping method is a more expensive option but also the fastest and least complicated. This is the service everyone is familiar with — if you want to send a box overseas to a friend via UPS, this is the option you’re using, with other familiar companies including DHL, TNT, and FedEx.

This is a “door-to-door” service, which means you book the shipment, sit back, and wait for the shipment to arrive. The carrier will take care of all the paperwork, and they will invoice you for any “customs duty” once the goods arrive (a variable amount depending on your country and the type of goods you are importing).

This is the fastest and most convenient option. It is suitable for high-value/low-volume products or when goods are urgently needed. Anytime you need goods delivered by air, and the total weight of your shipment is below 400 kilograms, the Air Courier method will be your choice.

Air Freight

If you’ve got a ton (literally) of goods that need to be delivered fast, you may be interested in sending it via Air Freight.

Basically, this method is commercial air shipping. It is vastly more expensive than sending via sea freight. Note that this is an airport-to-airport service and does not handle deliveries, so you’ll have to pay separate haulage fees (getting the goods from the airport to your door/warehouse).

Additionally, in not choosing to ship via Air Courier (where you’re literally shipping through major companies like UPS, TNT, and DHL, which take care of the customs for you), you’ll need a customs broker to clear the goods through customs, and you can expect a small handful of other charges. A good forwarder would be able to provide you with an all-in-one quote.

This method would be used pretty rarely — only when you’ve got very heavy goods in China (heavy enough that it will be cheaper than sending by Air Courier) and need them at your destination, fast. Otherwise, if below 400 kilograms, sending goods by Air Courier will be cheaper.

What’s the Difference Between LCL and FCL?

LCL and FCL refer to whether your goods occupy an entire shipping container. FCL is more efficient and less costly for a number of reasons, assuming you have the volume.

A single 20-foot container can take up about 28 CBM of goods, but what we find is at the 15 to 16 CBM mark, it makes more sense to go for an FCL, even if your container is not full. The reason is that at that point, the costs for LCL will begin to rise and make less economic sense, and if you switch to FCL, you can reap the other benefits of FCL, including the faster shipping times and less chance of damage.

Additionally, the shipping process will be different for LCL and FCL, and LCL tends to be slower. For LCL shipments, the process goes like this:

- The consignee sends the goods to the port.

- Another company, called the groupage company, will consolidate the goods in a single container.

- Then they clear the container under their name.

- The container reaches the destination.

- Then the groupage company will clear that container.

- They then de-consolidate the goods into individual shipments.

- Finally, they’re labeled and sent to the consignee.

If the groupage company doesn’t have enough LCL orders, they will wait for more orders to arrive before consolidating your goods, so you may have even longer delays. Additionally, with LCL shipments, the documentation process tends to take longer as well, as goods need to be sorted by the groupage company and thus could involve several parties with varying product types.

All of this is to say an LCL shipment takes longer. Expect delays, upwards of two weeks on both departure and arrival ports.

Chinese New Year — What’s There to Know?

You’re likely familiar with Chinese New Year, and you’re likely familiar with the fact that the actual timing of the holiday changes every year. The actual timing of Chinese New Year changes every year because the Chinese New Year is based on the lunar calendar, which does not at all sync with the Gregorian calendar to which we’re all accustomed.

What you might not be familiar with is the fact that CNY is the greatest regular disruption in the international trade world. Most importers tend to underestimate the impact Chinese New Year has on their business, and even experienced importers can be caught by surprise because both its date and impact are variable.

The first thing to mention: Once Chinese New Year hits, factories are closed for a month. Nothing gets produced for three to four weeks.

Secondly, most QC issues happen around Chinese New Year — both before and after.

- Before Chinese New Year: Factories are working overtime because they are under severe pressure from their customers to get the goods out before the holiday.

- After Chinese New Year: A large proportion of the workforce won’t return from their hometowns, as they find other opportunities or choose to stay with their family. This means you have completely new people working on your products.

Freight costs go through the roof at this time also, because everyone’s trying to get their orders out before Chinese New Year. We’re talking about as much as three to four times the normal rate. If you’re doing serious volumes and have no choice but to ship at this time, this extra cost can result in heavy losses.

It’s best to budget accordingly or, ideally, plan early and try to get your last shipment out three weeks before the last working day of the factory. Place final orders at least two months in advance — especially for sea shipments and particularly if you have longer production times.

People often think there are risks if their shipment is on the water at this time, which is not true. You’re just trying to get it out before everything shuts down for Chinese New Year.

Importing From China and Ecommerce/FBA

Having covered everything from finding your product in China to getting that product out of China, there’s still the matter of running an optimal ecommerce business driven by importing. We cover some of the basics below.

What Are Strategies for Buying and Improving an Importing Ecommerce Business?

Buying a business tends to be easier when the business has an established relationship with a supplier and at least a few repeat orders with them. That way, you can immediately get returns by reducing product cost. Once you’ve made the purchase, negotiate costs with the existing supplier or find new suppliers to source the same product at lower costs, and boom – instant cost optimization.

We have at least two clients that use this strategy — they acquire a business and immediately send us a product sample to see if we can cut costs by five percent or more. In some cases, where the cost savings are substantial enough, they would flip the business straight away for a healthy profit.

Alternatively, changing the way goods are shipped can also bring massive ROI, as in most cases, shipping costs can also be optimized.

What Are the Challenges Ecommerce Sellers Face?

With ecommerce, and specifically FBA, the biggest challenge compared to the traditional wholesalers and distributors is that the importer’s quantities tend to be smaller, while their customization requirements are larger.

From the factory’s perspective, this is the worst of all worlds, since their ideal is large orders with minimum customization. As such, the biggest challenge is getting suppliers’ support, and building a decent rapport and relationship with them.

The second biggest challenge is that you have to hold their hand in order for them to understand your requirements. This is especially true if you’re customizing the product, like changing colors and changing the packaging. For FBA stores, this is especially crucial, as Amazon has very specific packaging requirements in terms of the condition of the package, the cartons, the palette, the labels, etc. Factories just usually aren’t good at this because it requires a certain degree of detail orientation.

These two issues are clearly intertwined — in order to better ensure that factories are tending to your needs, you need to make sure your relationship with them is sound and that they care for your order, even if it happens to be small and customized.

Does FBA, Or Any Other ECommerce Platform, Have Different Requirements for QC?

There should not be a major difference when it comes to QC. Regardless of whether you’re an offline seller or an online seller, you still want to sell a quality product.

That being said, one common problem is that these importers tend to be smaller, without a full and comprehensive understanding of compliance requirements for their products.

Larger and established buyers have a good idea of what the compliance requirements are because either they’ve been in business long enough, consulted with compliance experts, or even hired a full-time compliance person.

Small distributors can learn about the compliance requirements and process by researching their industry, product, and country requirements, and partnering with professionals in China to ensure compliance needs are handled appropriately.

Should an FBA Importer Consider Not Shipping Directly to an Amazon Warehouse?

Should you choose not to ship directly to Amazon, even if your final target is selling through FBA, you have a couple of options:

- You send the goods to your warehouse.

- You send them to a third-party warehouse (“prep companies” as they’re known in the FBA business), which would then forward them to the Amazon warehouse after inspection.

There are a few reasons to not use FBA, even if selling on Amazon is your final target:

- You can keep your large volume in a warehouse of your choice and then drip-feed into FBA, as this keeps some of your FBA costs down because third-party warehouses generally tend to be cheaper than Amazon.

- A third-party warehouse might be able to help with ensuring QC, as goods can be damaged in transit (this is more likely with LCL than with FCL) and therefore some FBA sellers will get them re-inspected on arrival at the destination before sending them to FBA warehouses.

Nonetheless, most importers have a preference for sending everything directly into FBA because of its convenience and speed. Speed to market is a critical factor — the faster you rotate your products, the more profits you earn, and Amazon is particularly good for this.

With your products shipped, there’s only one thing left to do, and it’s what you’re best at — marketing and selling. We leave it to you to be the expert on that end of the spectrum.

Bringing It All Together

With importing from China, there is a steep learning curve which is compounded and complicated due to the language and cultural barriers. There’s a whole universe of minor details that can be learned only through experience.

But here’s where you’re at now: You’ve got the most important industry terms down. You know how to find and do due diligence on suppliers and then communicate and negotiate with them for the terms of your import project. You also know the fundamentals of ensuring your quality is controlled as tightly as possible and then how to get all the goods from China to the U.S.

As the old cliché goes, the rest is just details.

Photo Credit: Macor

Discussion

we would like to hire some qc company to check our production soon. it seems imex is a good option.

Let us know how it goes 🙂