3 Steps on How to Manufacture an Ecommerce Product

When you decide to start an online business selling a particular product, you go through a process of figuring out exactly what the right product is for you to sell.

You need the perfect product, and you want it to be produced well. All your effort shouldn’t go into the idea phase. Deciding which product to sell is important, but finding the right manufacturer to make that product is just as important.

Finding the right production partner takes some time and research. It doesn’t have to be hard, but you have to do some due diligence.

Fortunately for you, we’ve distilled the process into three steps. Let’s look at how to go from brilliant idea to finished profitable product.

Step One: Find Your Product

What are you going to sell?

Maybe you think that’s the easy part, and to some extent, it is. You figure out what you want to sell, and go find a supplier.

One strategy (often used by Fulfillment by Amazon sellers) is to find a product that already exists and figure out how to make it better. Read through the negative reviews, for example, and then come up with a way to fix what past buyers have disliked about the product.

The reason why this strategy works is that you know someone can make this product, and you know there’s a market for it. All you have to do is improve on it.

Start by searching for existing products and suppliers on marketplaces like Alibaba. The supplier may or may not also be the manufacturer, but it’s a place to begin.

Do your research; find out what kind of market exists for this product and read through product reviews from the end customer on Amazon or other seller sites.

Make sure you purchase the existing product so that you can test it. You need to see the product in action so that you can decide how to make the product better. Should it be bigger or smaller, come in different colors, be of higher quality, have other bells and whistles?

You want to make the product better, but keep in mind that making it better means that manufacturing it has to be achievable. Don’t get too wild with your updates — fix the problems, don’t create new ones.

For example, if your product is a cheese grater that everyone loves, except that the holes on one side are too large, your goal could be to create a cheese grater with holes that are smaller.

Once you’ve decided what product you want to sell and the changes you’re going to make, you need to find the right company to manufacture it for you. This production partner is a critical part of your business strategy, so it’s important that you perform due diligence to find the right one.

Step Two: Find Your Manufacturer (and Negotiate)

It’s time to start shopping around for manufacturers for your product and negotiate with them to produce the product you’ve decided to sell.

This step is research heavy; you’ll want to make sure you’ve answered a few questions, done some homework and some legwork, and reviewed a sample product. If you like lists, you can take the bolded phrases in this section and put them in a handy checklist.

The first thing to consider is where do you want your product to be manufactured? You can choose a manufacturer in your own country (domestic) or a company outside your country (overseas).

Choosing a manufacturer based in your country has some advantages. First and foremost, it’s easier to communicate with them. You’re in the same time zone, or at most a few hours ahead or behind, you are more likely to share a language, and there’s a better chance that you can visit the factory in person to see how things are done. Shipping may also be less expensive.

An overseas manufacturer has its advantages as well. Production costs are likely to be far lower, and you’ll probably have more factories to choose from. And it is becoming easier to work past language barriers.

Once you’ve decided on the general location for your production, it’s time to dig into the research. Which companies are able to produce the product you want to sell?

You can find a potential manufacturer by searching through directories like Alibaba, visiting trade shows, and asking for referrals.

You can also hire an agent to help you, which is an especially good idea if you want to manufacture a product overseas. An agent that you trust and that knows the local manufacturing scene can take a lot of the pressure off of you, especially if there’s a language barrier.

The most important thing is to talk directly with the potential manufacturer. Unless you’re meeting at a trade show or similar business event, your first contact will probably be via email.

Keep that initial contact concise and clear. Many manufacturers (like all of us) are inundated with email, so get to the point and let them know you’re serious.

A few things you want to ask about in that first email:

- Minimum order quantity — What’s the smallest amount of product you can order from them?

- Production pricing — Do they offer discounted pricing if you order higher product quantities?

- Turnaround time — How long will it take them to make your product?

- Payment terms — Do you have to pay for the full order up front, or on delivery? If they want the full cost up front on the first order, are they willing to negotiate for subsequent orders?

Once you’ve established contact with a potential supplier, it’s best if you can follow up your initial contact with a visit to the factory in person, or have your agent visit. You need to see the factory to know if they can actually manufacture your product. Look for how well the factory is organized, how production lines are set up, and how the operation runs overall.

The leg work is intensive, but if you want to do your research right, you need to be hands-on with this part of the process. You don’t have a business if you don’t have a product to sell, yes? So take the time and get this part of the process right — do the research in person to make sure that the factory is able to produce your product the exact way you want it done.

You want to get quotes from a few different suppliers, if you can. Make sure you’re comparing apples to apples (for example, things like same quality of materials, or same estimated production lot).

Once you have narrowed down your potential suppliers, you want to ask them to produce a sample product for you to review. That way, you know how they are translating your requirements into form and you can ask for changes if they didn’t get something correct.

Depending on the factory, you may have to pay for the sample, though they may offer it at a discount.

Solid communication is the basis for any good partnership, and working with a manufacturer is no different. You need to provide all the details for your product: dimensions, weight, color, packaging, shape, texture, and anything else that affects your product.

There’s no such thing as providing too much information — if you want your product to be a certain way, you have to communicate that information to the manufacturer.

Once you get the sample, put it through testing. Does it perform like you want it to? Is it made to your specifications? Does it look like you thought it would?

Reviewing the sample is your opportunity to make sure that the factory can and will build the product the way you want it done. Testing it is your way to know that the function and quality of the sample product is what you’re looking for.

You can also check for quality and production costs, plus any other unexpected information you and the manufacturer learn from making the sample. Did it cost the manufacturer more to make the product than they thought? Take longer to build?

This part of the process lets you work out any kinks in the system. Sure, you’re still going to run into challenges down the road (e.g., shipping, customs, holidays in the country where your factory is located), but if you don’t work out the foundational process of getting the right product made, you’ll never make it to those challenges.

Step Three: Consider Quality Control and Product Delivery

You’ve chosen a product, negotiated with a manufacturer or three, and reviewed samples from those manufacturers.

Now comes the fun part: ordering your product to sell.

Your manufacturer is going to ask you for a purchase order, and if they don’t, you should offer one. This binding document is the official agreement between you and the manufacturer. It specifies the product (and any details) that your supplier will make, and the quantity you will purchase for the agreed upon cost.

Be specific and be thorough. If anything goes wrong here because you left something out, you’re stuck with the result.

You’ve inspected the factory’s production process, but you may want to go back and inspect the final product. Even if your initial research process shows that your chosen factory has good internal quality control processes, it’s a good idea to double-check the quality of the end result.

You may also choose to hire a third-party professional to inspect the product during production and before shipping, or you can manage that function in-house (meaning you or one of your team members visits the factory to inspect the product).

Plan your delivery timeline wisely, and make sure you’ve taken into account things like customs and holidays. If you’re shipping product from an overseas factory, it’s just going to take longer. If you need product by a certain date, plan backward from that date and consider holidays, weather that might impact shipping, and the customs process.

Once you’ve sold all your product, you can go back to the manufacturer and set your next order. There are so many new businesses looking to manufacture products these days, and just like you, manufacturers are looking for good business partners. If you’re happy with your product, and it sells like you hoped, then you know you’ve got a good business partner and a long, profitable relationship ahead of you.

Manufacturing a Product Is Easy

If you’re ready to start an online business, or if you’re purchasing a business and looking to improve it, there’s a whole world of things you can sell. Choosing the right product for you can be an overwhelming process, but with a little research, you can find the right item to manufacture and build a successful business in the process.

A few things to remember:

- Communication is key. Be clear when communicating your requirements to a potential supplier, and visit them in person if at all possible.

- Ask the right questions, and consider things like minimum order and turnaround time.

- Do your homework; make sure the product is exactly what you want, but also that the factory processes are what you need.

- Be specific in your requirements throughout the process.

With due diligence, finding the right partner to manufacture your product can lead to the beginning of a beautiful — and profitable — friendship.

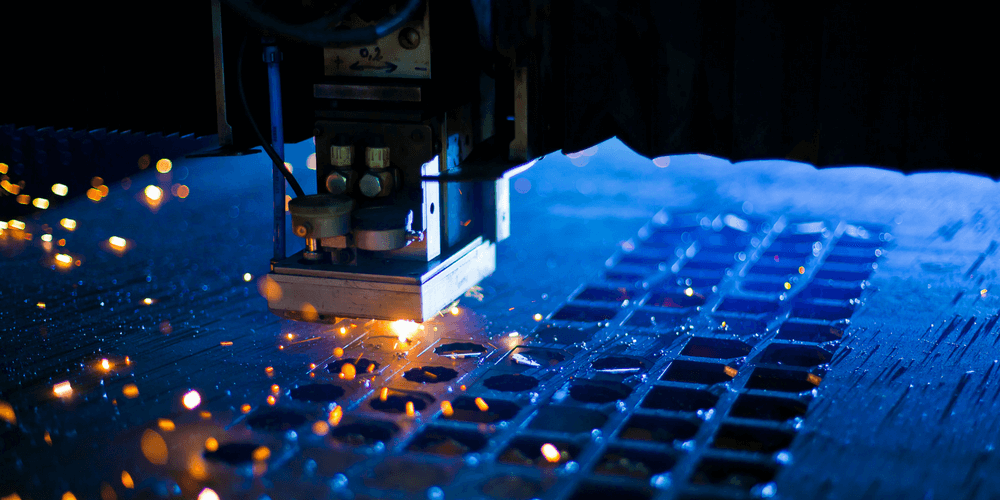

Photo credit: nikkolia