Demand Forecasting: How to Avoid Under and Over Stocking

After searching for an option and finding something they want to buy, “out of stock” is probably the most frustrating message a potential customer can see.

Not to mention, it actually prevents them from giving you money.

Managing inventory is a foundational aspect of building an e-commerce business. Without inventory, you can’t make sales, so inventory needs to be considered a top priority.

Inventory management entails everything related to inventory, from finding suppliers and arranging storage to delivering products to customers.

For e-commerce through Amazon FBA or Merch, there are some key differences.

Amazon fulfills all orders, whether they’re sold on the Amazon marketplace or not. They have warehouses where FBA store owners can keep inventory, and they handle the shipping of products and some of the customer service involved.

Regardless of whether you own an e-commerce store or an FBA, you’re responsible for one key element of inventory management – demand forecasting.

What is Demand Forecasting?

Demand forecasting is predicting how much inventory you’ll need to fulfill future orders. This is usually based on past sales data, i.e. how many units you sold the same month/season in previous years. Your inventory demand is also influenced by public holidays, world events, national sales, or your own marketing campaigns.

It’s important to keep on top of your inventory levels, because if you run out of stock your customers will not only be frustrated by not being able to purchase your product to help them with their needs, but they will question whether your store is reliable and organized enough to carry out the basics of actually getting the product to them and meeting delivery times. That’s before they’ve even seen the product to judge it’s quality – not a great start.

Overstocking to make sure you never go short couldn’t hurt then, right? Just make sure the warehouse is always full.

Not quite.

The downside of having too much inventory on hand is that it results in high storage fees. And if your items are perishable, you risk losing inventory that is stored past its expiry date. So, poorly-calculated overstocking will push you towards the red.

As with a lot of things in life, it’s about balance.

When you get your inventory levels as close to demand levels as possible, the benefits are extensive. Beyond having more satisfied customers, doing so can save a lot of money wasted in storage fees, purchasing more inventory than is needed, and losing perished stock. When you account for changes in order volume, you also save on inventory carrying costs, as the warehouse saves on labor associated with handling goods. This is all money you can use in other areas of your business.

You’ll also be getting the maximum amount of sales possible from your marketing efforts and from the regular demand your business experiences. Again, this means more money that would have otherwise been lost through stock-outs. If you consider the lifetime value (LTV) of your customers, you’ll see how valuable one well-executed sale can be.

Understanding demand forecasting takes the guesswork out of inventory planning. Instead of ordering more inventory when you need it, you understand your production cycles, i.e. manufacturer’s lead times, warehouse receiving timelines, and the exact stock levels you need for each product. When you have a solid understanding of all of this, you can make informed decisions when changes happen, such as when you decide to launch a new product or when a big world event likely to increase sales is due.

Staying on top of your inventory helps you keep on top of your business. Let’s look at how it’s done.

How to Forecast Demand

Arguably the most effective way to forecast customer demand is to look at your own past sales data. What recurring trends do you notice? Do you have a seasonal product that sells 10x more in the summer?

It’s also important when forecasting to take into account how your business has changed over the years. Are you seeing consistent year-on-year growth? What effects do your product launches and marketing campaigns usually have on sales? The answers to these questions are key to forming more accurate forecasts.

Beyond influencing factors that are unique to your business, there are some fundamental precepts that all e-commerce owners can follow.

A Simple Formula to Use When Forecasting Demand

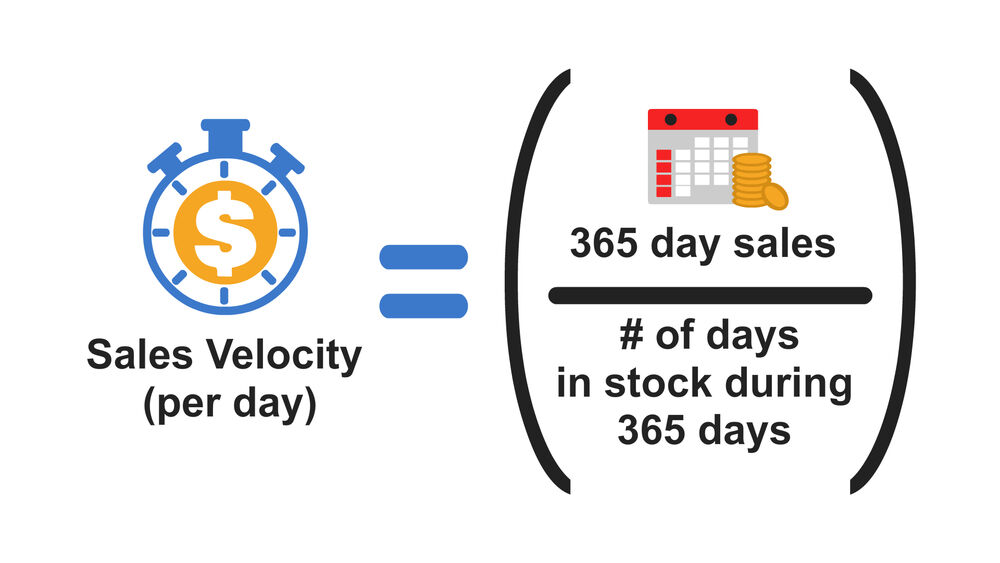

The first value to consider is the sales velocity.

This is the rate at which you sell your product, for example, 30 units per day. It’s a better metric than average sales over a number of months, as you may have had stock-outs that limited sales. We want to know how much you’d sell if you were always fully stocked.

You should do this for each of your products, as some of your products will fly off the shelf faster than others. You can also do this for sales by marketing channel if it’s different from organic search. That will help you forecast better for your marketing efforts.

Once you calculate your sales velocity, you have a baseline to go off of. Generally, you shouldn’t be stocking lower than this number, unless you experience particularly low sales off-season.

The next values to consider are the order forecast and replenishment.

Order forecast is the predicted number of orders you expect to receive over a time period you set. For example, it could be over 30 days if you’d like to know your sales for the next month.

Replenishment looks at how you’re going to fulfill those orders, by considering three factors:

- Your current stock levels – this is how much stock you have in your warehouse right now ready to be shipped to customers.

- Lead time – this is how long it takes to receive the inventory at your warehouse from your supplier. You want to account for your lead time when ordering inventory to avoid going out of stock.

- Stock on order – this is how much stock there is currently in transit from the supplier to your inventory warehouse.

Let’s go through an example of what this could look like in practice. We’ll start with a business owner – let’s call him “Tim.”

Tim sells laptop chargers.

After carrying out an order forecast for the next 30 days, he’s expecting to receive 300 orders from his customers. He has 60 chargers on hand and his lead time is three days. Since he expects to sell an average of 30 laptop chargers over the next three days (300 orders/30 days = 10 orders per day), he will be left with 30 chargers and 27 days’ worth of orders to fulfill. Since his 30 chargers will cover him for another three days, he needs replenishment of 240 chargers to be able to cover the next 24 days of orders. Therefore, his next inventory order, which takes three days to arrive at his warehouse, should be for 240 chargers.

This is a simplified formula to use as a guide. Of course, every business is different with its own unique circumstances. You should always consider how this guide fits into your situation specifically, and use your judgment to make accurate inventory orders.

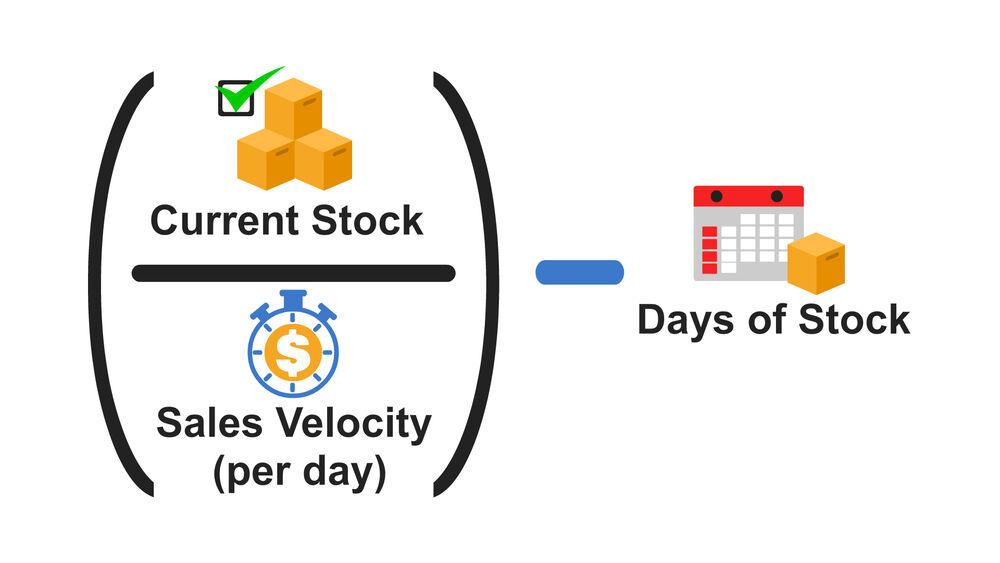

Quick Check – Are You Over or Under Stocked?

Now that we’ve learned how to forecast demand, let’s see if you’re over or understocked, or if you happen to be right on the money.

First, you want to factor in your lead time when deciding how many days’ worth of stock you need before your next order. Then you want to consider your sales velocity to see how much stock will be used over that time.

Stock levels are calculated as follows:

If you’re overstocked, you can potentially delay your next inventory order, unless you have perishable goods. If so, you might have to conduct a sale of some sort to quickly shift items that are near their sell-by date. Otherwise, after your current stock is sold, you can better organize your demand forecasting to help avoid future overstocking. You may incur some extra storage fees this time around, but at least you have gathered information that will help you make a better decision next time around.

If you’re understocked, then you know you need to order more inventory soon to avoid a stock-out, at least where this is possible.

These formulas and theories are applicable for steady, predictable sales. But what about when things change with your business or in the marketplace?

Situations When You May Need to Change How You Forecast

As we mentioned before, probably the most effective way to forecast future demand is by looking at your past sales data. This is also true when planning for seasons.

Season Planning

For the most part, seasonal businesses come in two forms; they are either heavily seasonal, these are businesses that sell for short seasons with products like Halloween costumes or Christmas decorations. Or they are gradually seasonal, these are businesses that sell for long seasons with products like sun hats or wooly gloves.

If you have a seasonal business you can look at previous years to see when customer demand started to increase, peak, then decrease. When you’re coming up to those seasonal months, it’s best to give your suppliers advanced warning so they can prepare to meet your demand. This is where having multiple suppliers can really help a business – if one cannot meet the demand, the others can act as a safety net.

You can use the sales velocity formula here, too. Just take into account the length of your season.

For example, if your season has shown through past sales data to last 90 days, then you would calculate your inventory ordering like so:

Remember, this is an average, and your sales could vary quite a bit. So make sure you also take into consideration how long your stock will last in the warehouse if you sell perishable goods.

If your lead time is 30 days, then you need to order the extra stock 30 days in advance to be ready to meet the demand.

Product Launch Planning

Of course, with a new product, you won’t have any sales data to go off of, but demand forecasting still doesn’t have to be guesswork.

In this case, you could use sales data from similar products you have if your new product is a variation of those (i.e., different sizes, shapes, or colors).

If it’s completely new, you could send an email survey out to your customer list and ask them how interested they would be in this new product. A lot of interest shown in the survey results would mean that you should probably prepare for a high-order count.

If you don’t have a customer email list or any past sales data to go by, then you can always carry out a pilot test launch. This is where you launch a product with a small amount of inventory to see how many orders you receive. If you receive a lot of orders, then you can probably assume the demand will be quite high, and you can order a higher amount of inventory for the final launch. If the order count is low, then you should be cautious with how much you order for the final launch.

Forecasting for Promotions

Again, we go back to looking at past sales data.

How did your past promotions affect sales? This is the best way to get an indication of predicted demand; however, you should also consider any stock-outs or extraneous factors that might have affected this data.

If you haven’t got any sales data for previous promotions, or if this promotion is completely different, then when you carry out the marketing build-up to your promotion, you can analyze your email open rates or your social media engagement rates as a guide to see how much demand for this promotion there will be.

If you’re launching a sudden promotion without any build-up, then it will be difficult to predict demand. You could always reach out to e-commerce communities on Facebook or Reddit or other social platforms and ask store owners in a similar or the same niche for advice and about their experiences.

As with product launches, you can also run a pilot test of the promotion for a shorter period. For example, if you’re planning to launch a 20% off campaign for one week, you could launch the campaign for one day and see how much demand there is to forecast for the full seven-day promotion.

All in all, the most important thing to consider with promotions is how much you can give away. Make sure you have a limit on redemptions of your promotion because you can risk going out of stock and losing a lot of money by underpricing more stock than is necessary for the promotion. We know of businesses that made this mistake and paid a heavy price.

Another important factor to consider is how seasonal demand or other changes in the market, which include big events (e.g., sporting events), will affect sales. Be sure to take these into account when forecasting for promotions.

Online Business Buyers Like Poor Inventory Management

This year, we conducted a return on investment (ROI) study for Amazon FBA acquisitions. In that study, we found that 32% of online business buyers identified optimizing inventory management as their main growth strategy.

We have even had an Amazon FBA owner successfully sell their business with us recently, despite having poor inventory management that led them to stocking out and overstocking multiple times, which was costing them money.

It’s a desirable trait of a business to some buyers because they know they can quickly increase earnings by making a few straightforward changes.

Without these skills, some e-commerce owners find it difficult to get over that hurdle to scale their business. They decide to sell their business instead of investing money and resources into scaling.

If you’re in a similar situation and are not sure whether to try and scale up or cash out and reinvest in other ventures, then our friendly team would be more than happy to give you some expert advice on a free phone call.

Conclusion

This is just one aspect of inventory management we’ve covered today – there are many more sub-topics to explore to get a full grasp of inventory forecasting – but hopefully this article helps you understand how to avoid costly over and understocking, which can limit a business.

If you’ve been considering selling your business at this point in your entrepreneurial journey, then have a go of our valuation tool and see what it is worth.